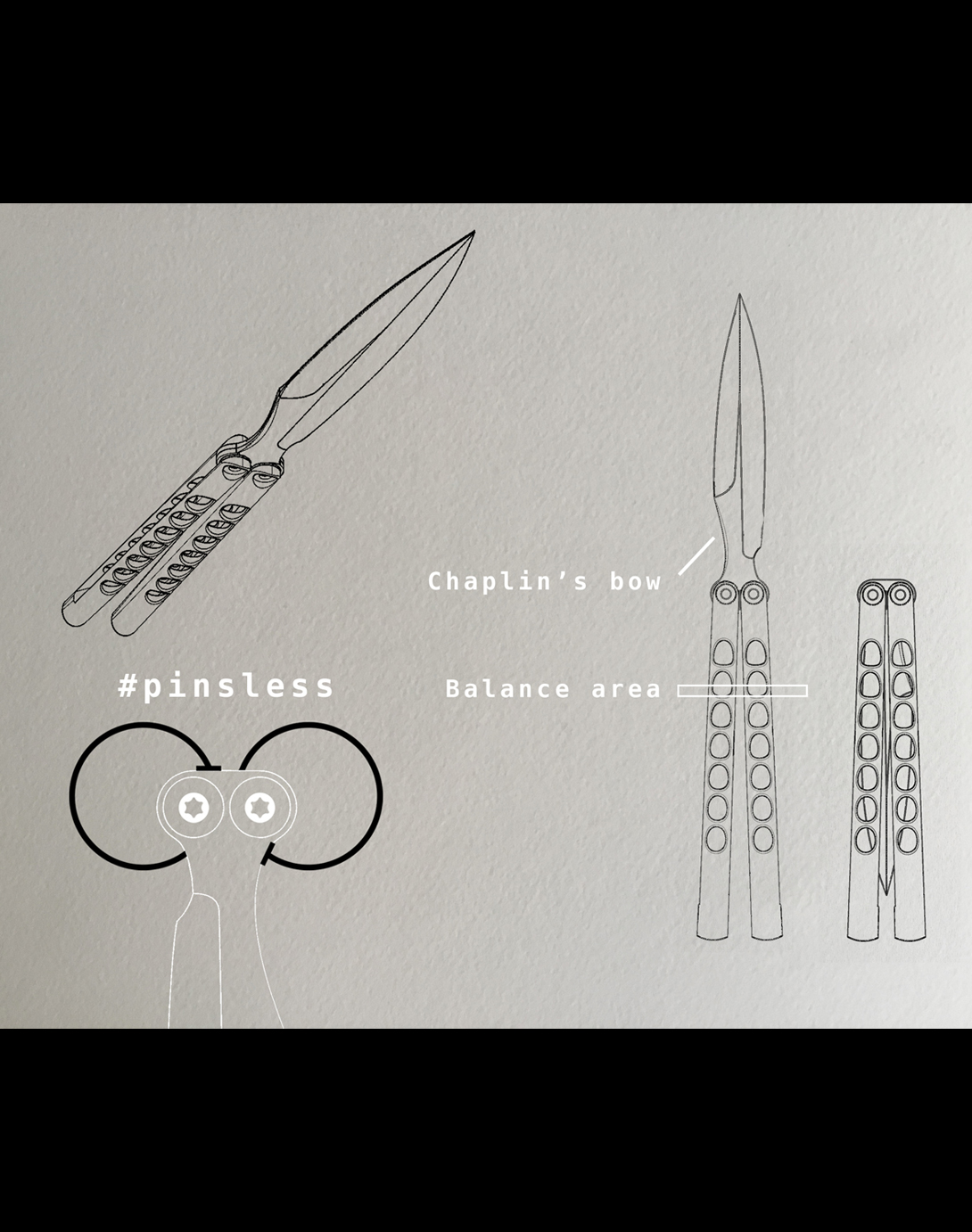

Pinsless System

I was looking for a functional design with a minimal aesthetic for my balisong project; so I tried to subtract and not add elements, thanks to these reflections in 2018 I developed the Pinsless system.

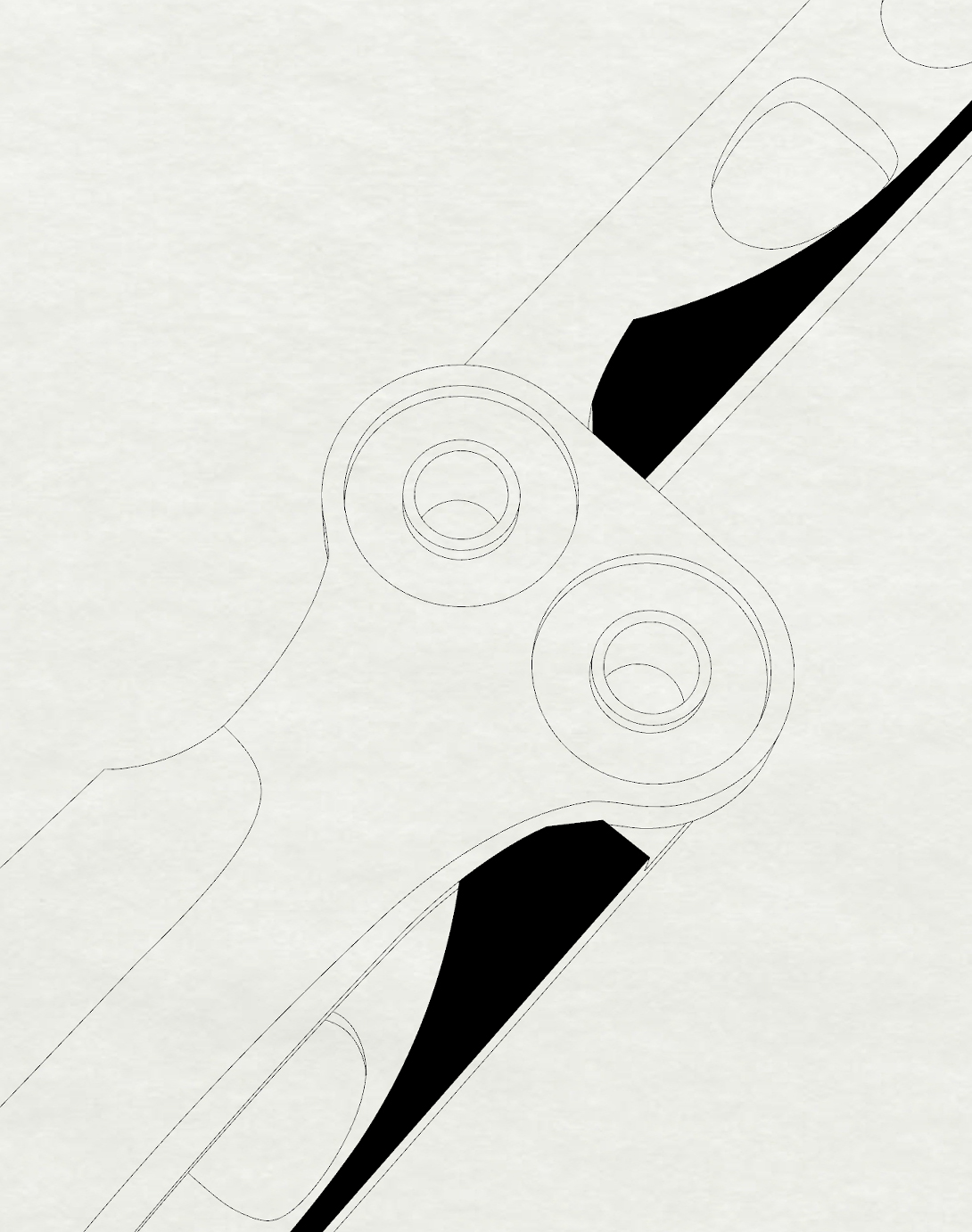

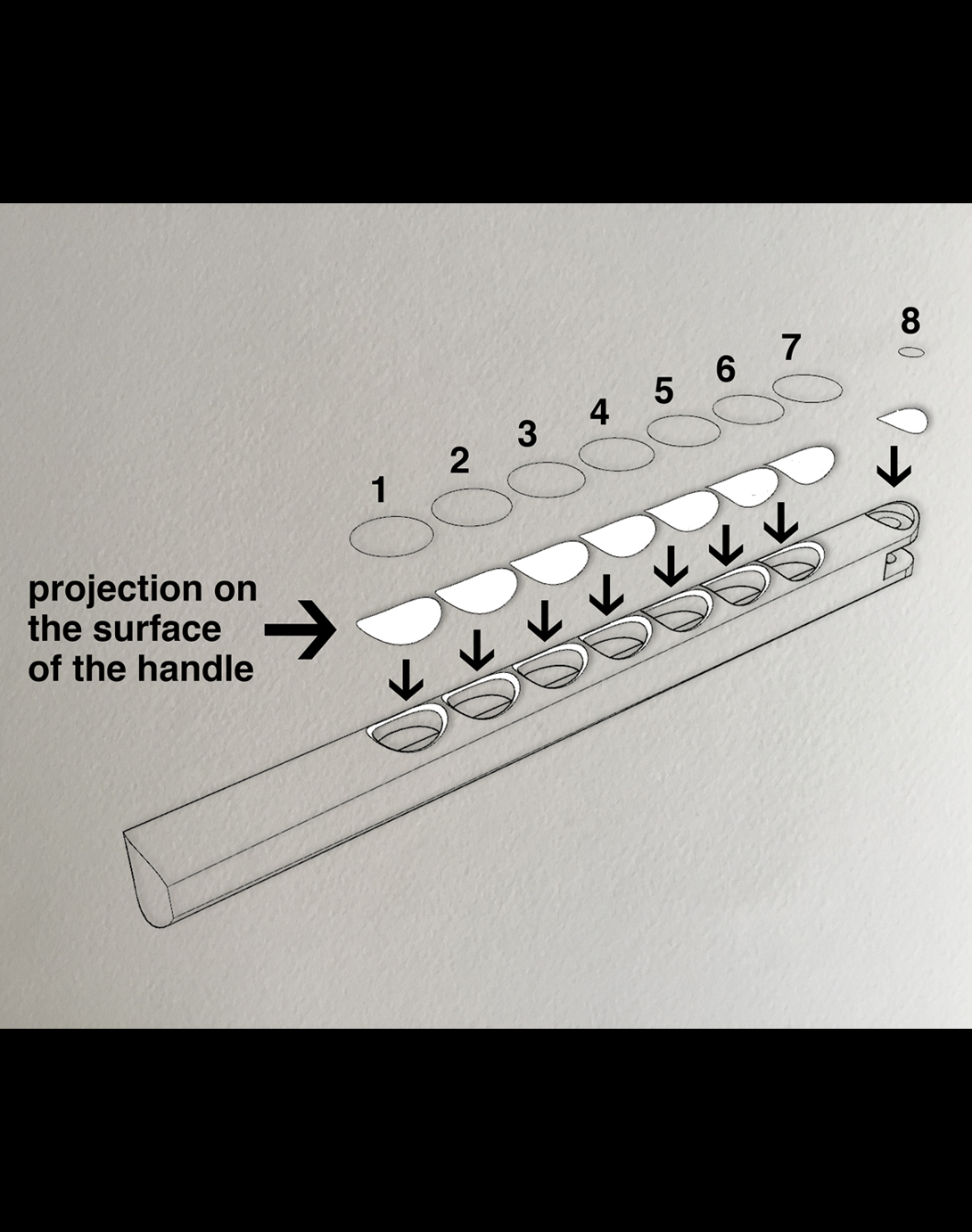

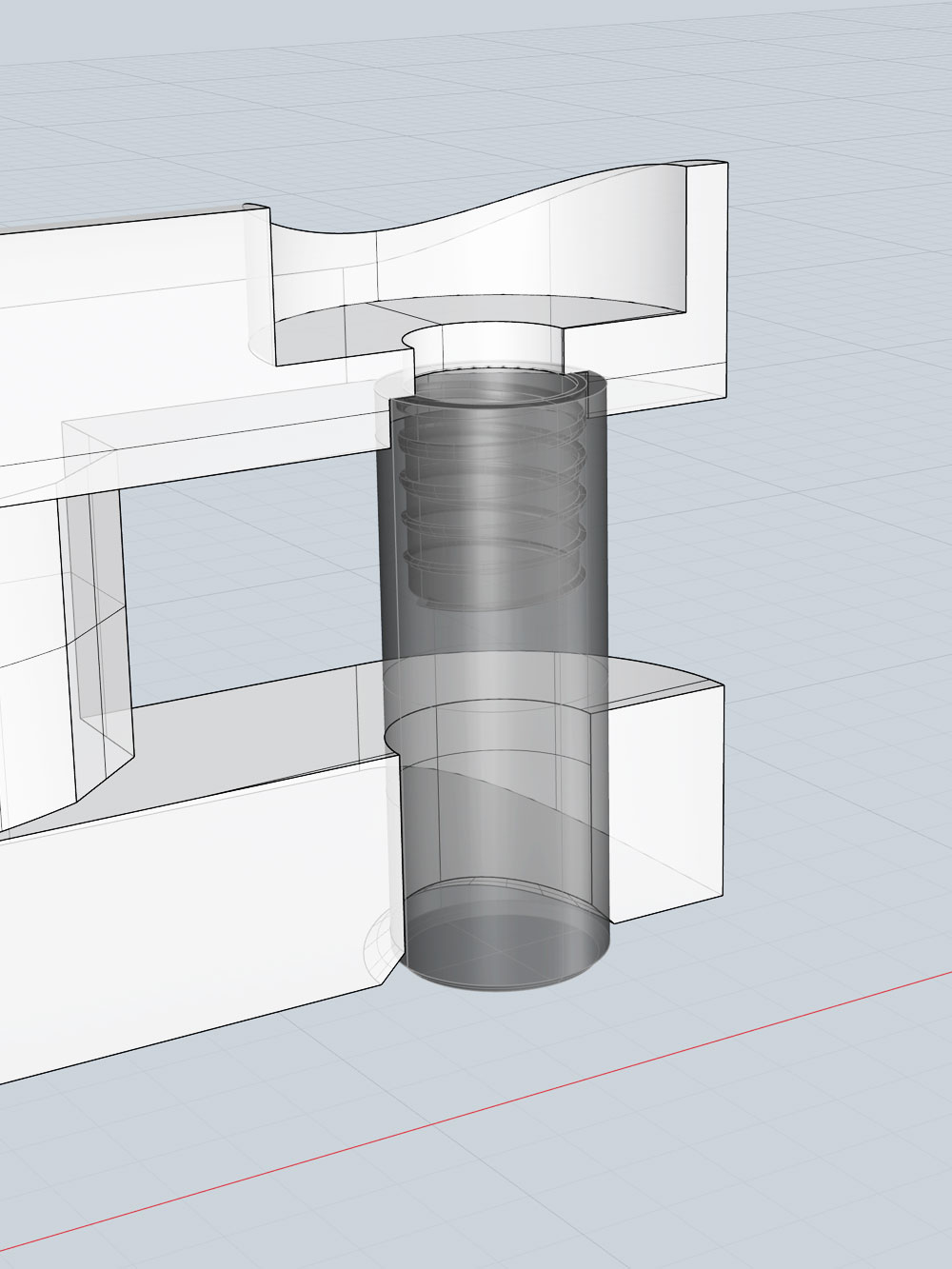

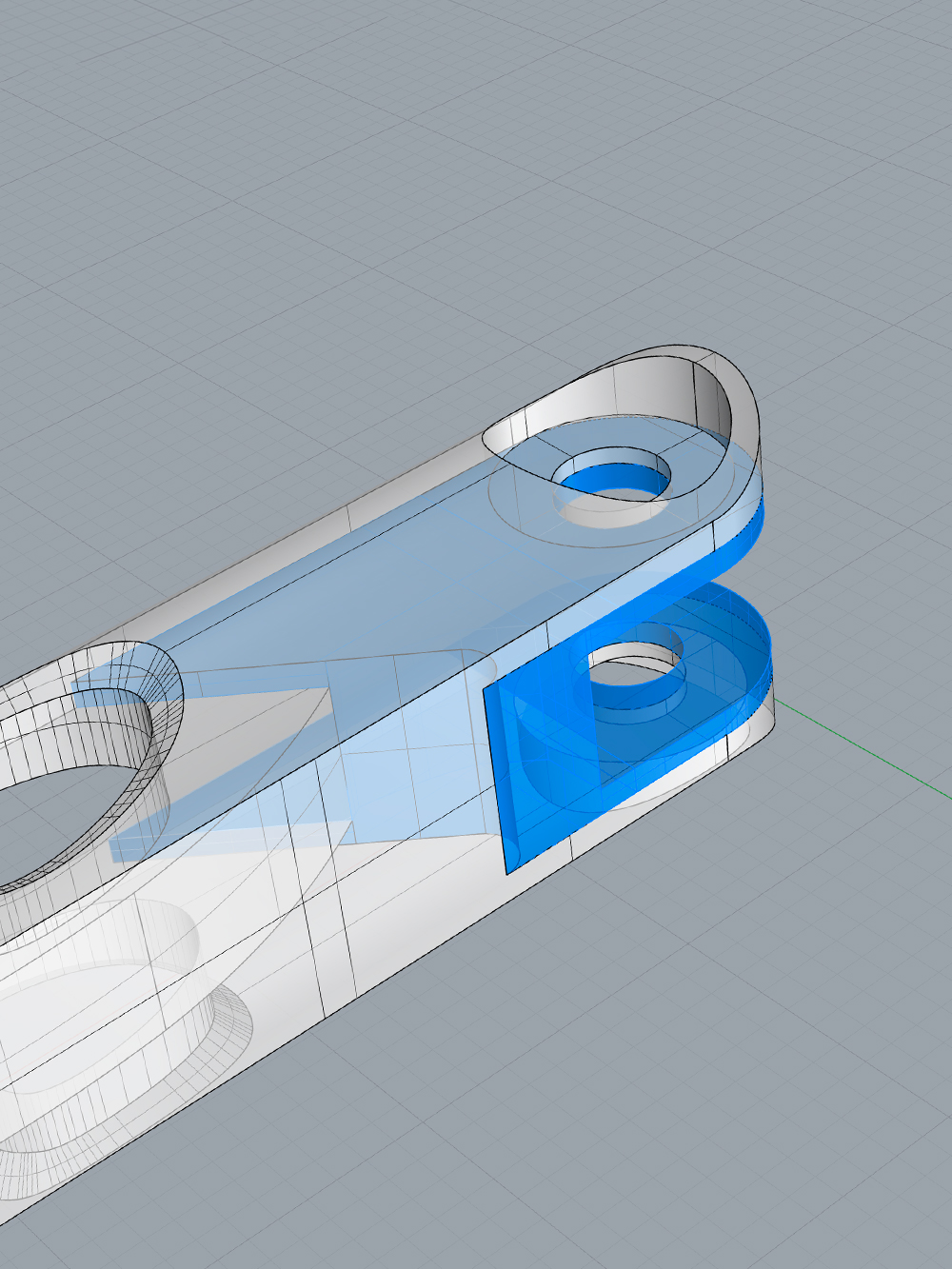

A specific milled geometry inside the integral handle channel creates solid setbacks between the blade and the handle without the use of any pins.

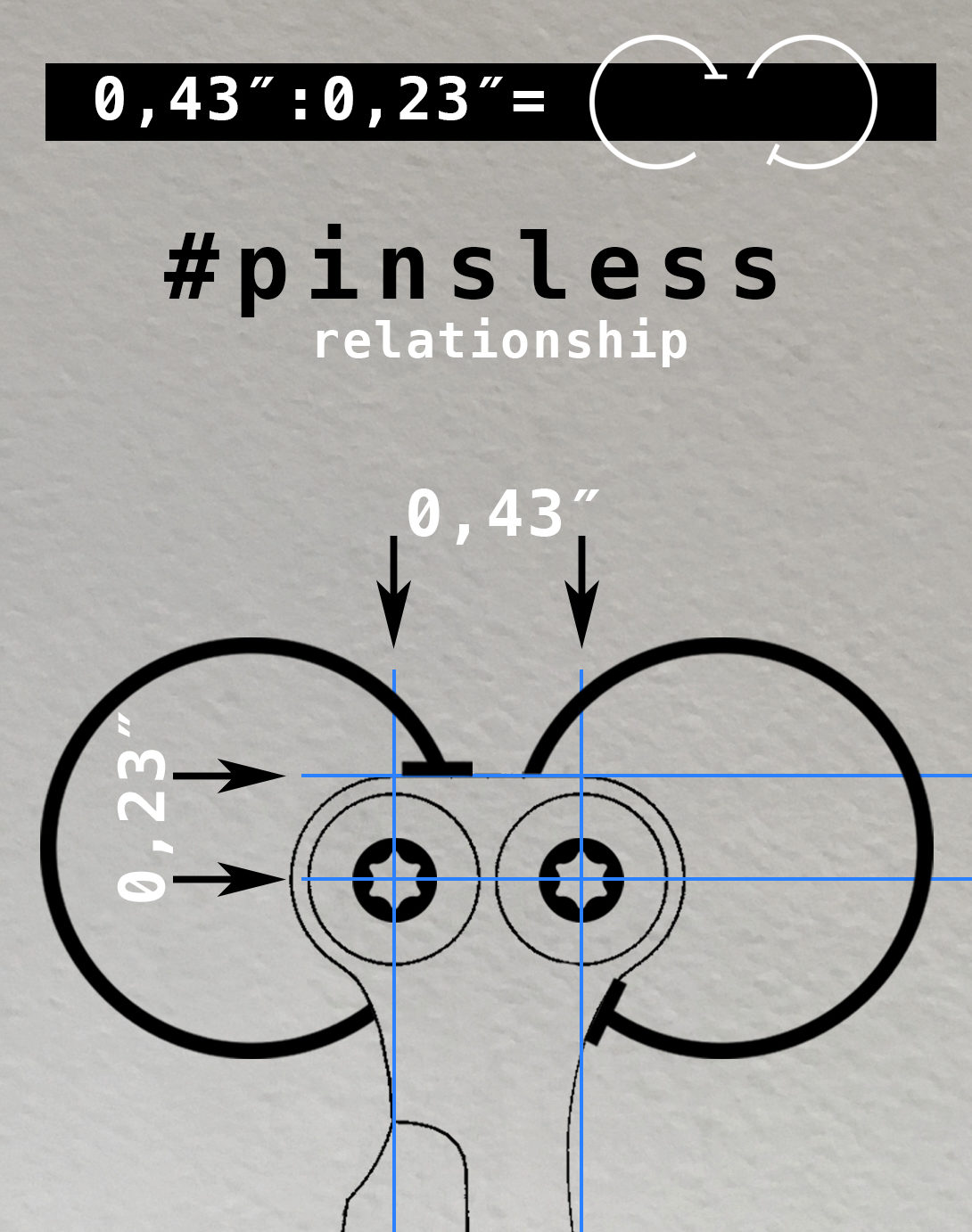

I have minimized the distance between the center of the two holes and distance between the center of the hole and the outer perimeter of the blade head (where there is the nipple in the zen pins).

This allows to work better with the center of rotation of the balisong.

So thanks to the particular characteristic of the Blade Head and the Chaplin’s Bow, the Pinsless system brings the fingers near the center of rotation of the balisong.

Video

A great selection of combos showing how the Pinsless system works!

Thank you so much to @the_italian_flipper whose talent honors my balisongs.

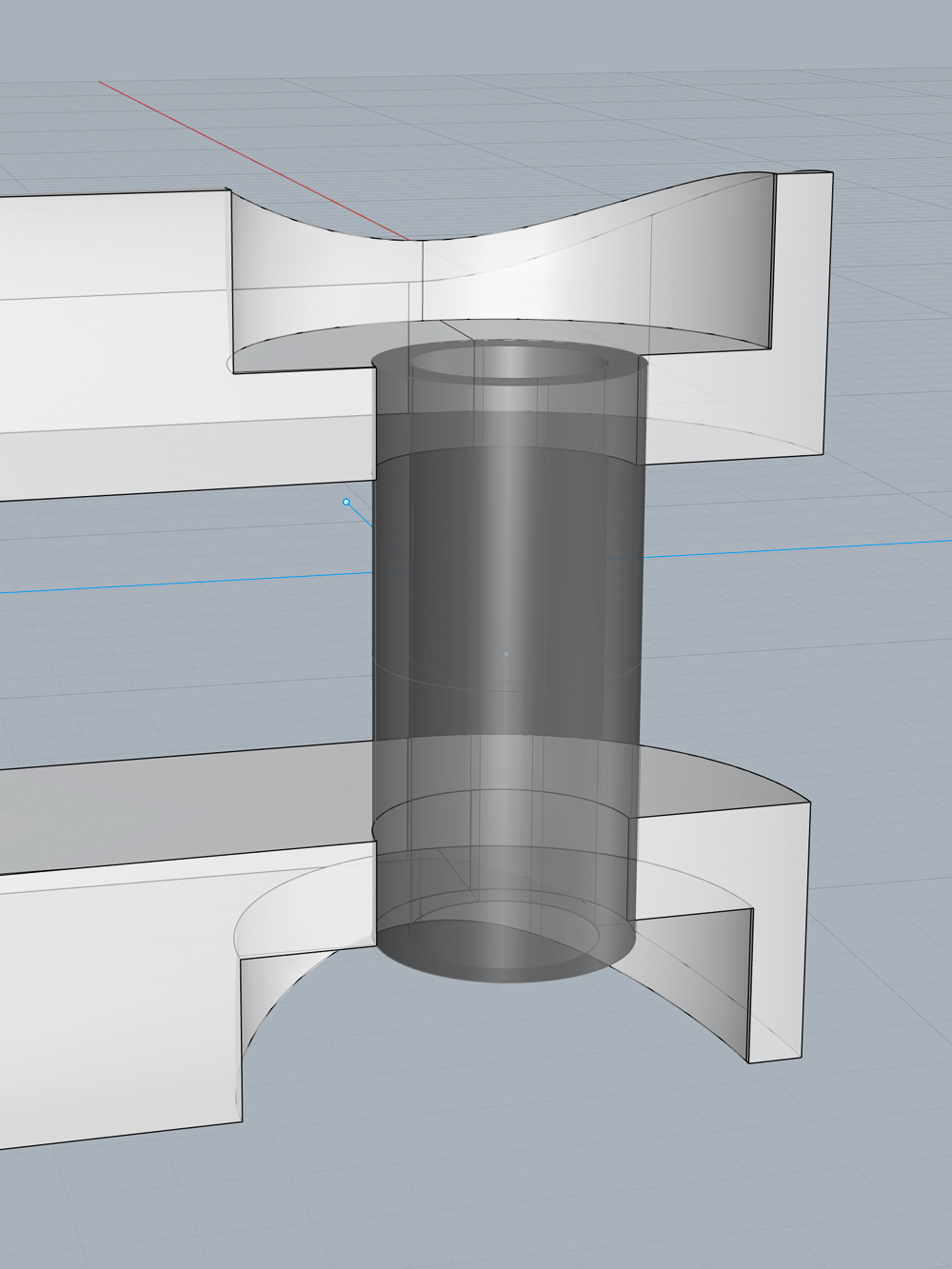

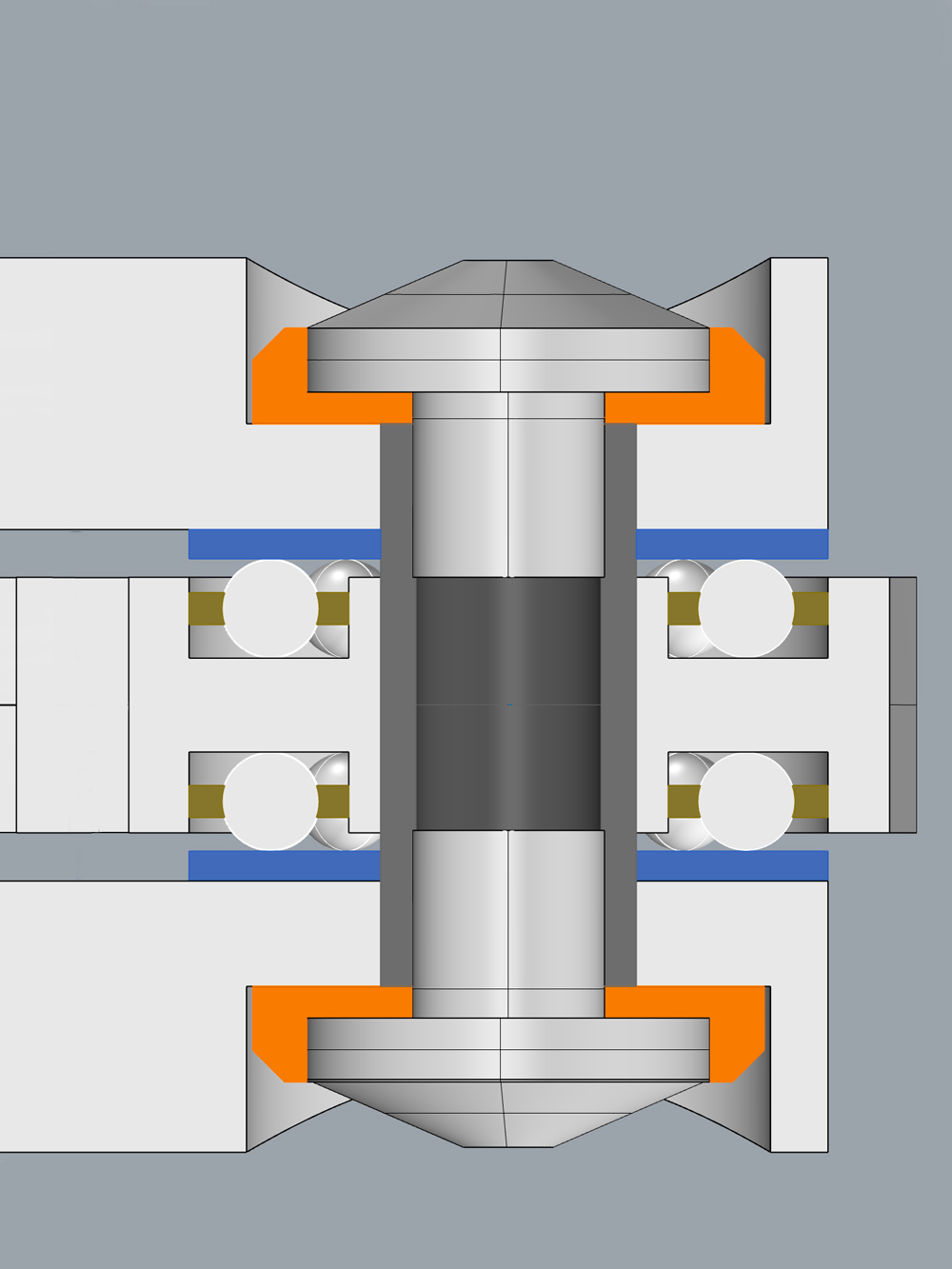

Aligned Pivot Barrels System

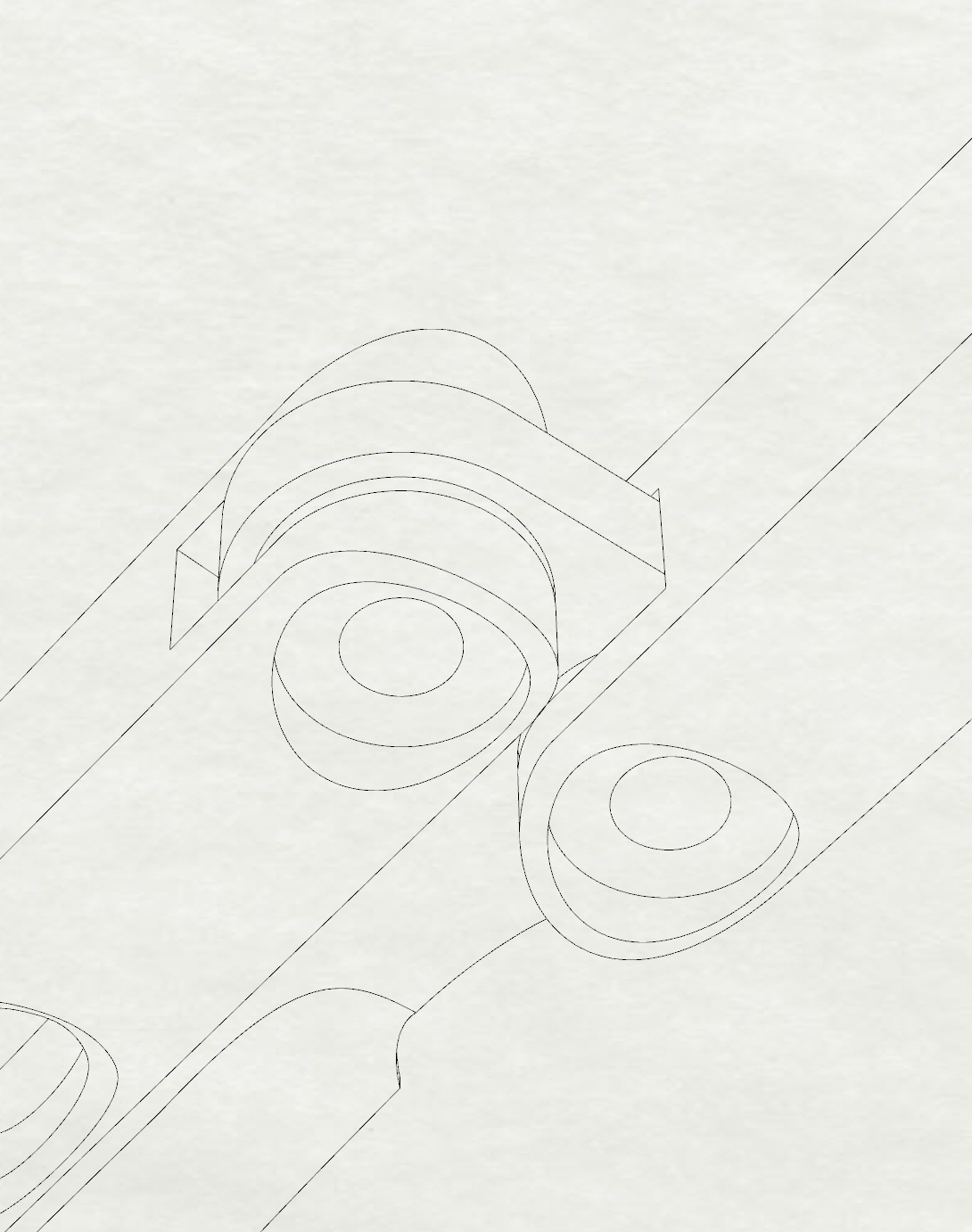

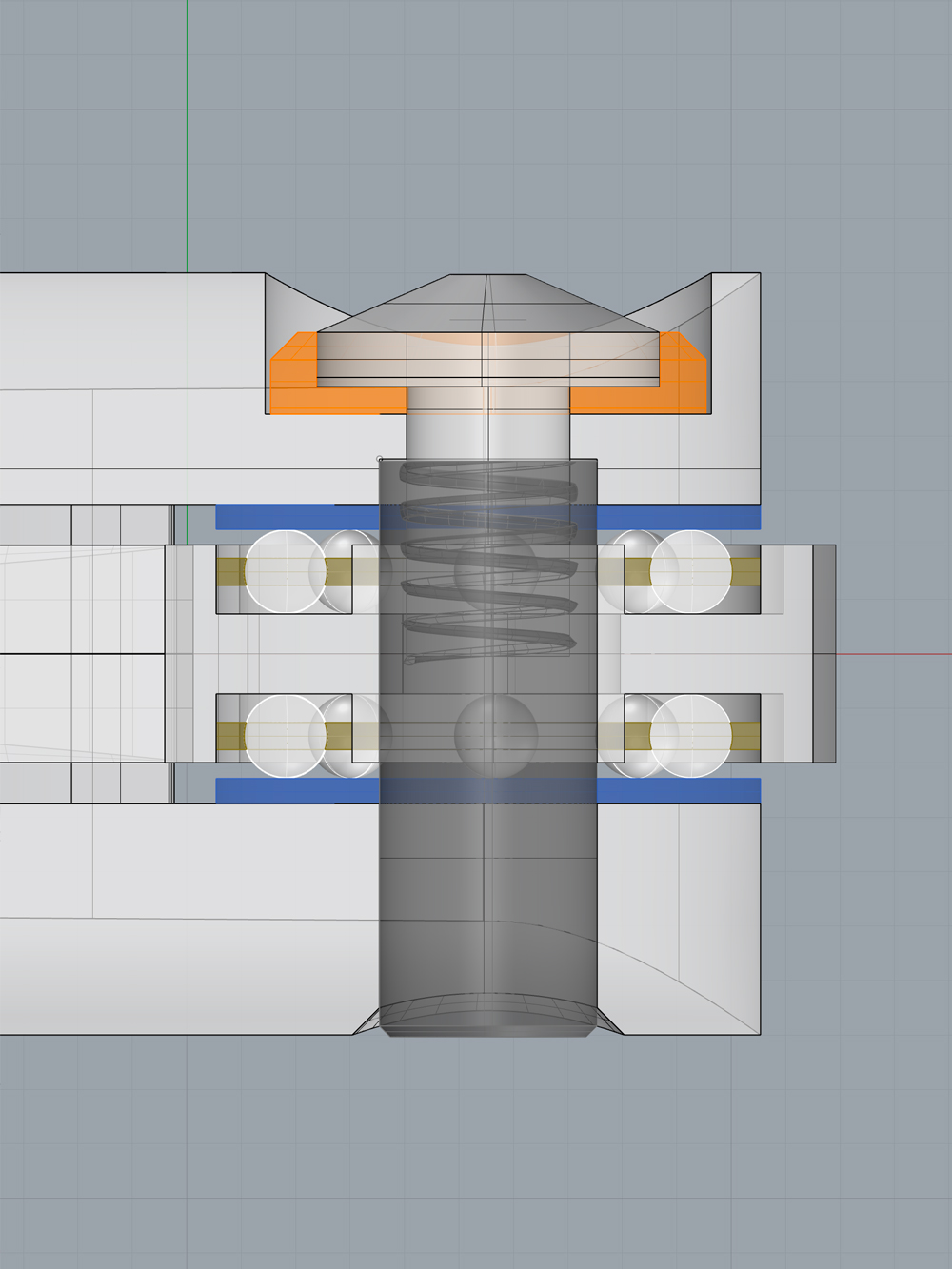

The screws and pivot barrel are torqued providing a clamping force (preload) to the overall joint, the pivot barrel aligns perfectly with the base of the counterbore this creates a spacer that allows the blade to slide smoothly while tightening the two screws firmly. In this pivot design the mechanical fit between shaft and bore has extremely tight tolerances, h7 (0 / -0.012 mm | 0 / -0.00047244094488”) H7 (0 / + 0.012 mm | 0 + 0.00047244094488”).

A hardened steel washer is inserted above the ball bearings, this is manually tuned to obtain the correct tolerance and 0 play between the handles.

- Ti 6Al-4v Torx T10 screws + Ti 6Al-4v collars

- Ti 6Al-4v / 17-4 PH Precipitation Hardening Stainless Steel (42/44 HRC) pivot barrel (h7 tolerance)

- SS ball bearings / Zro2 ball bearings

- Hardened steel washer

Barrel Plug System

This system requires the use of a single torx screw and a threaded barrel plug up to half section. The screw is torqued to the plug, a vertical tension allows to maintain an extremely tight h7 tolerance with the hole, the blade remains free to rotate smoothly and the play between the handles is zeroed thanks to the hardened steel washers above the ball bearings. Some integral folding knives already use this system in the stop pin, I think that its practicality and precision are also well suited to manage the coupling between handles and blade.

- Ti 6Al-4v Torx T10 screw + Ti 6Al-4v collar

- Ti 6Al-4v barrel plug (h7 tolerance)

- SS ball bearings / Zro2 ball bearings

- Hardened steel washer

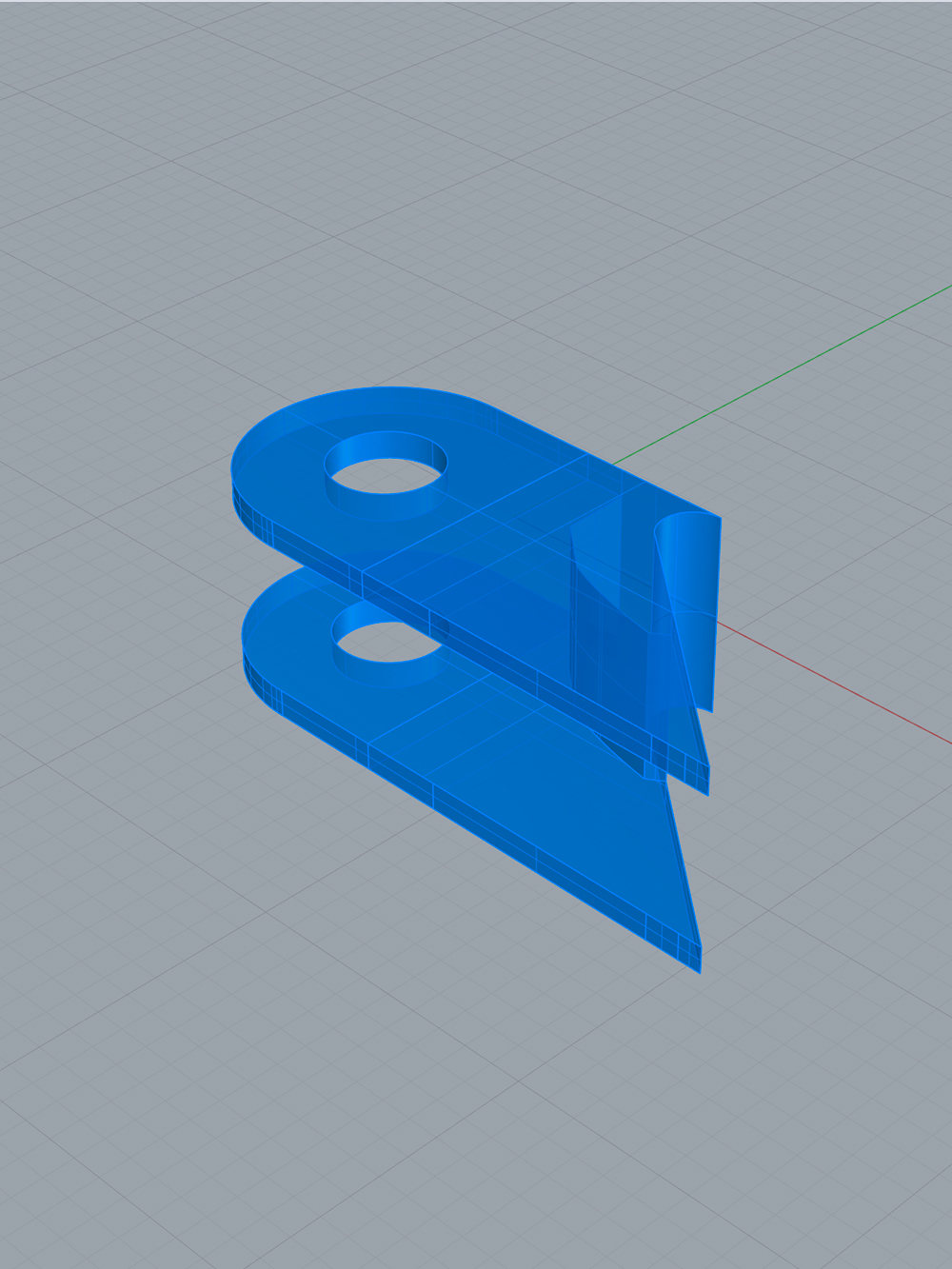

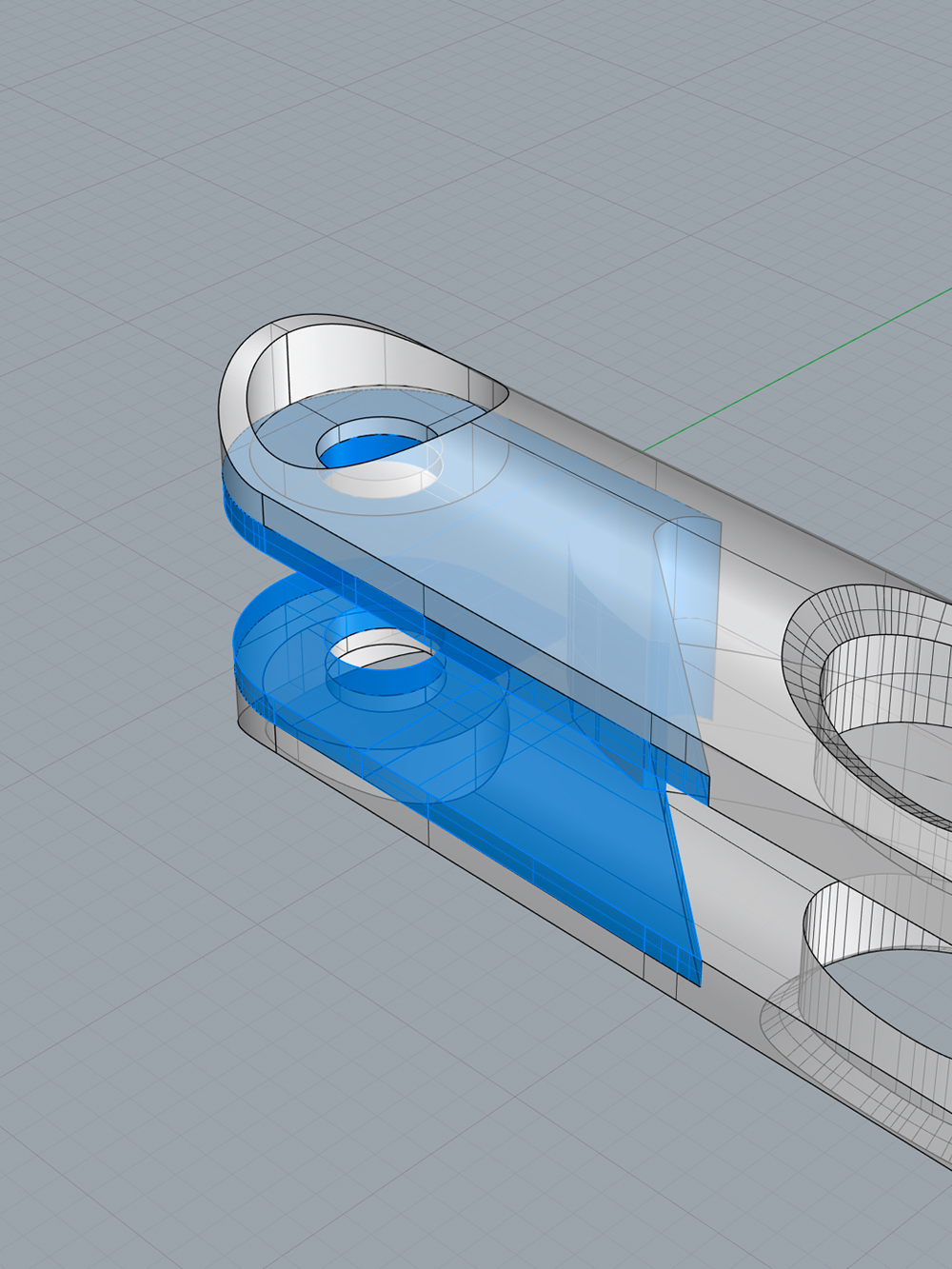

Integral stop blade insert

Some alloys such as ZircuTi or Timascus are softer than grade 5 titanium so the Pinsless system would risk creating deformations in the handle. This integral insert has the task of protecting the points where the blade hits the handle. The milled geometries in the integral channel of the handle allow the insert to fit perfectly without the use of any screws. Furthermore, the integral insert allows to guarantee the h7 tolerances!